|

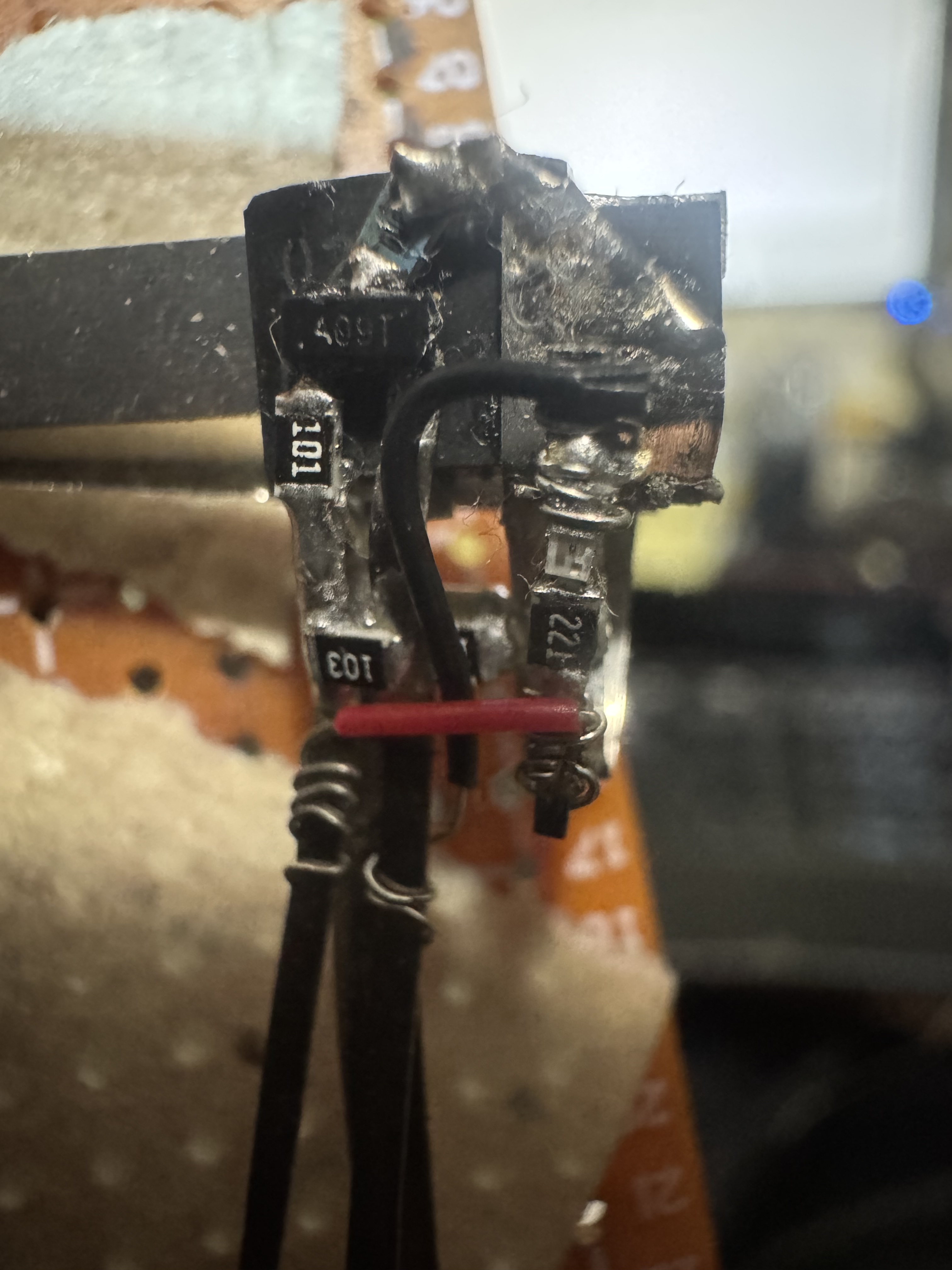

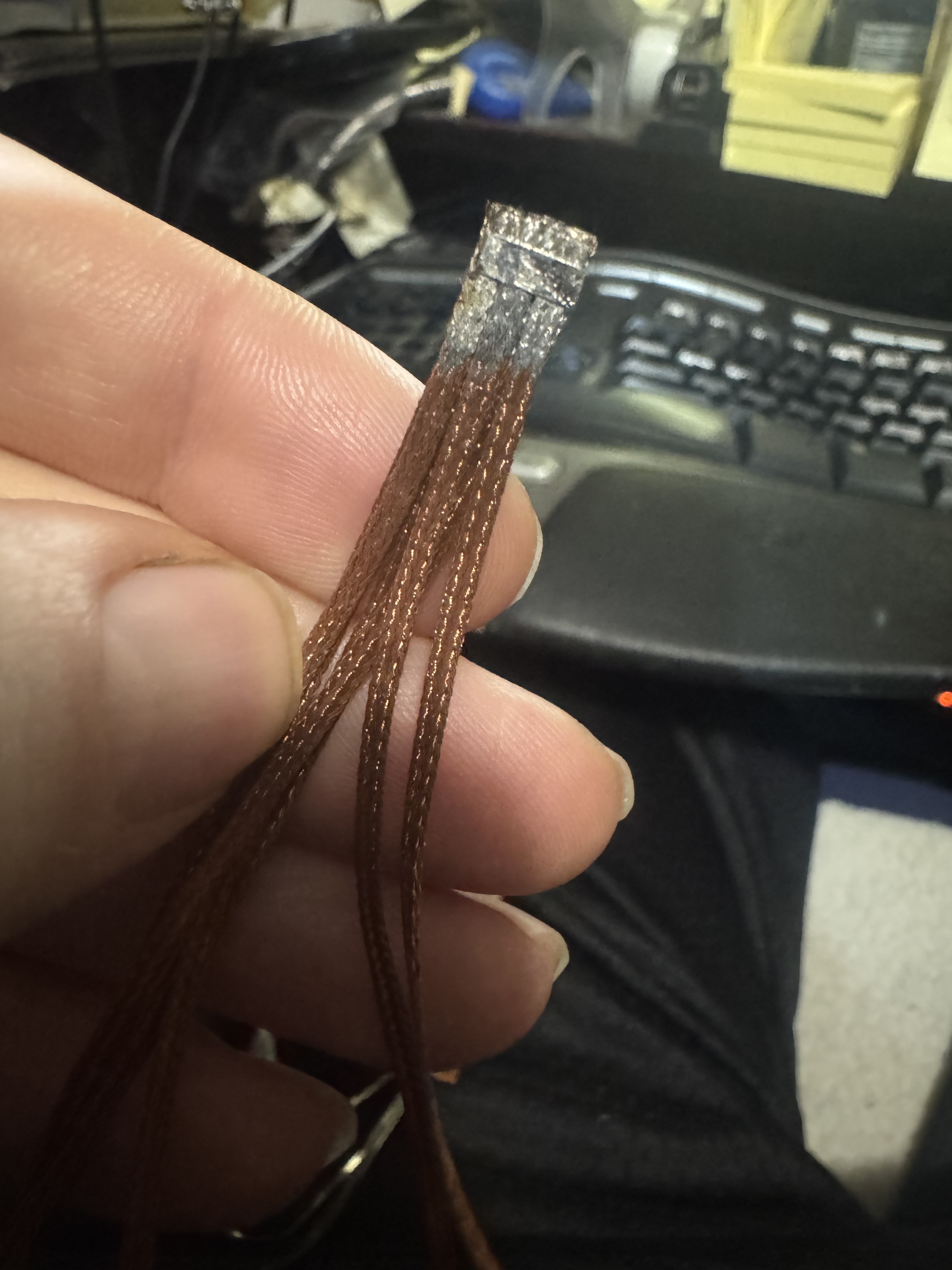

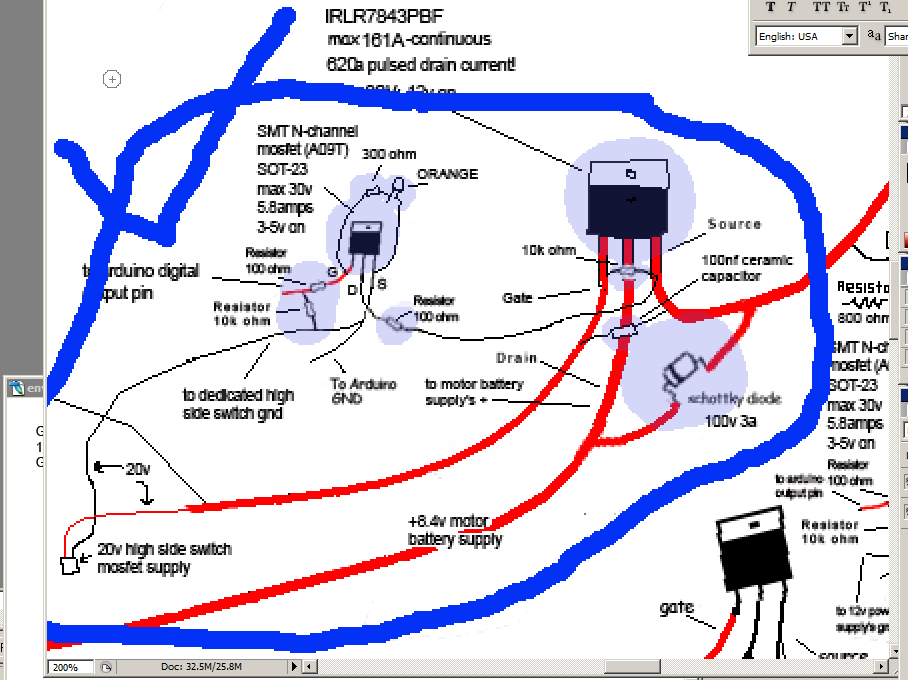

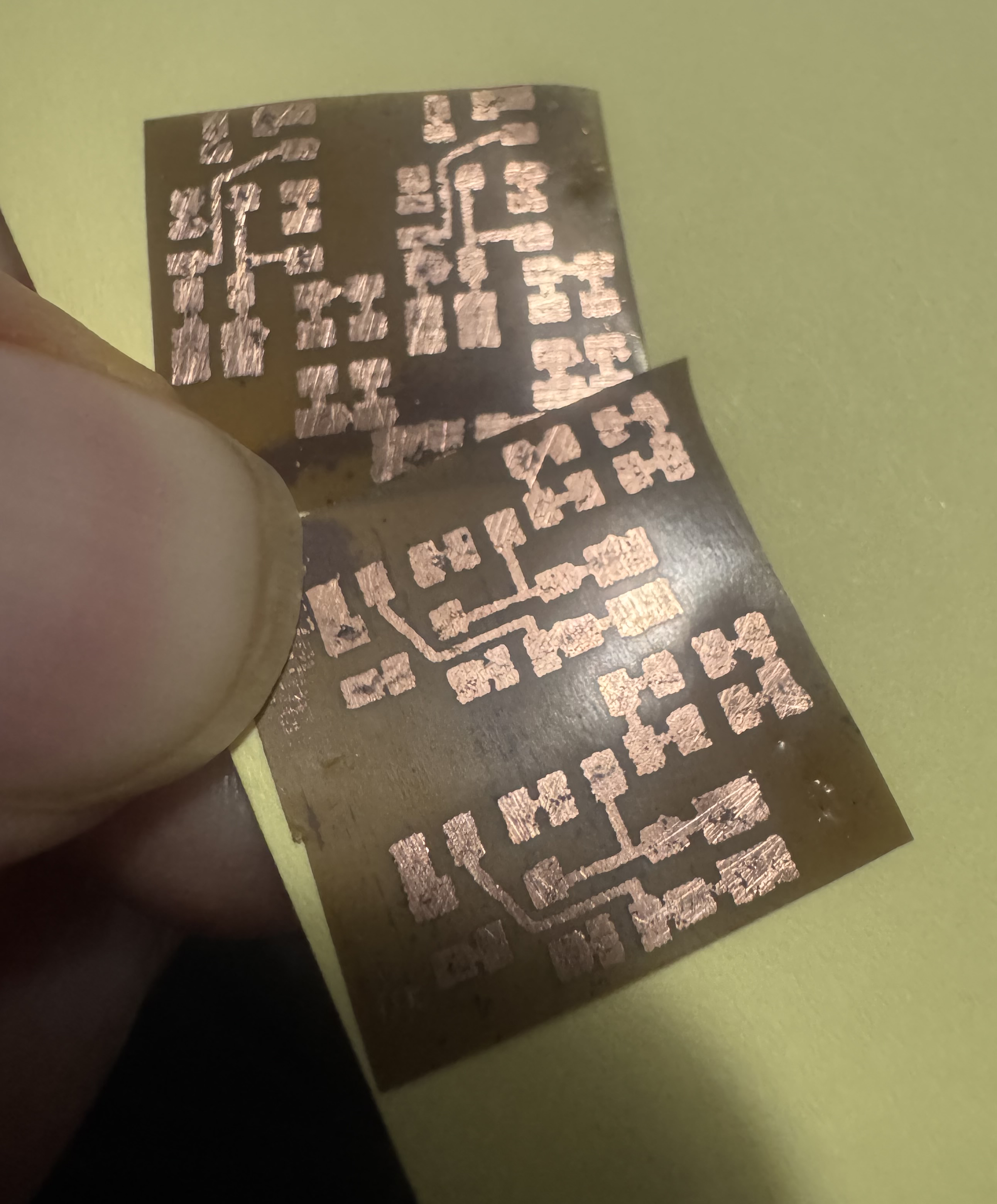

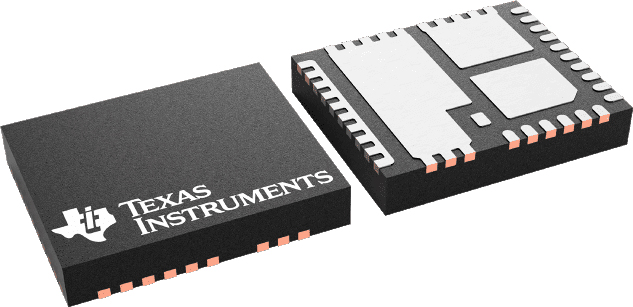

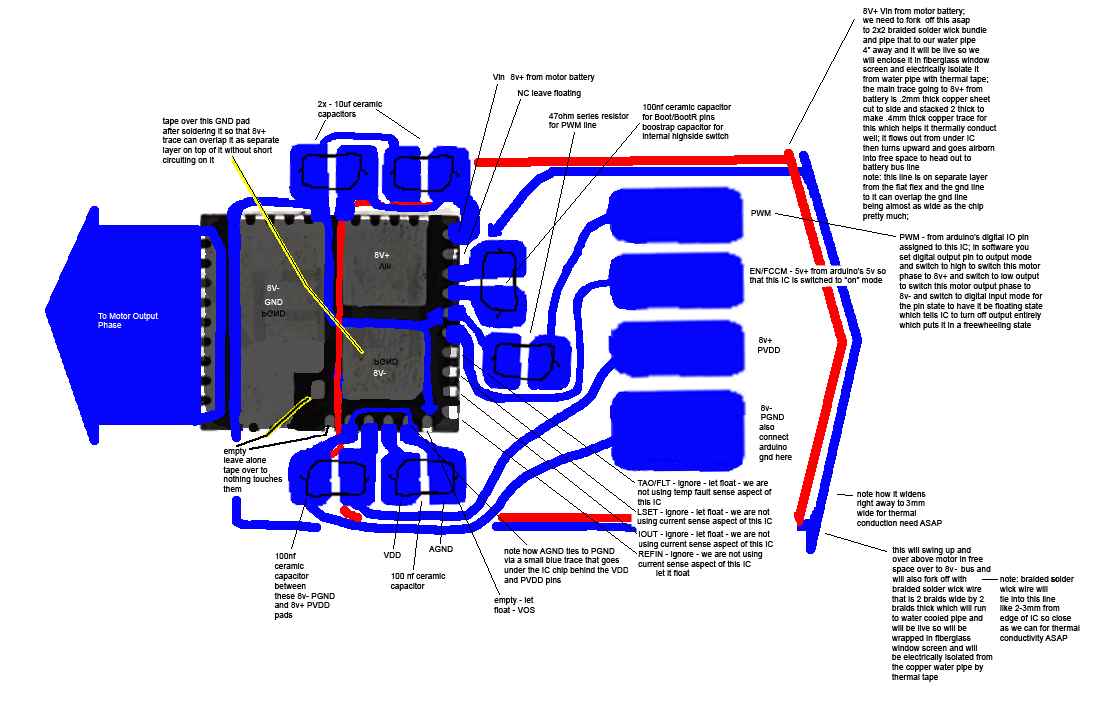

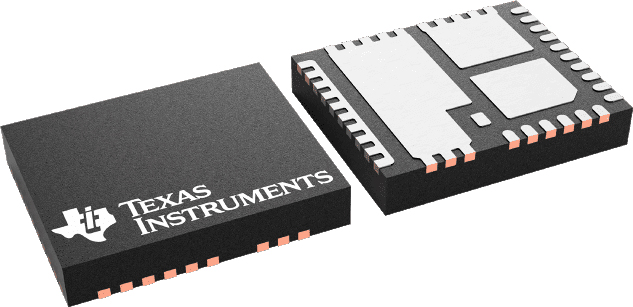

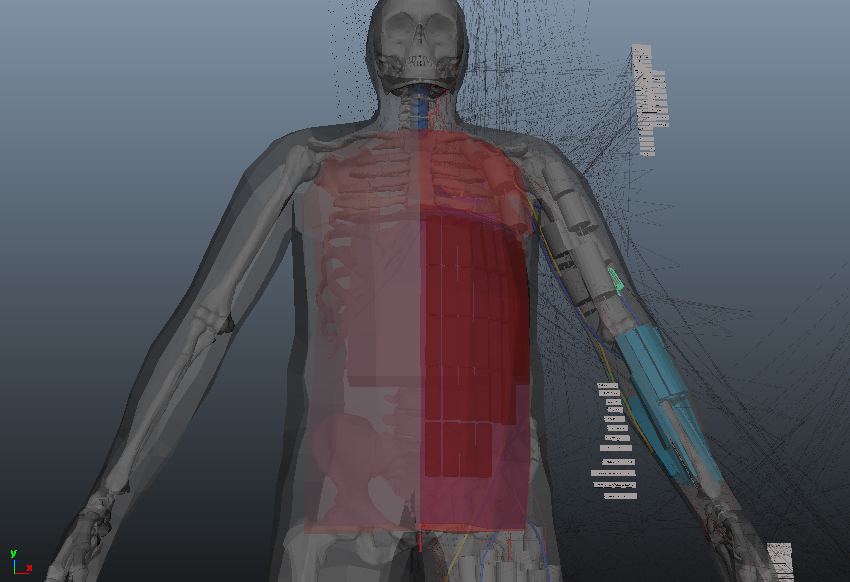

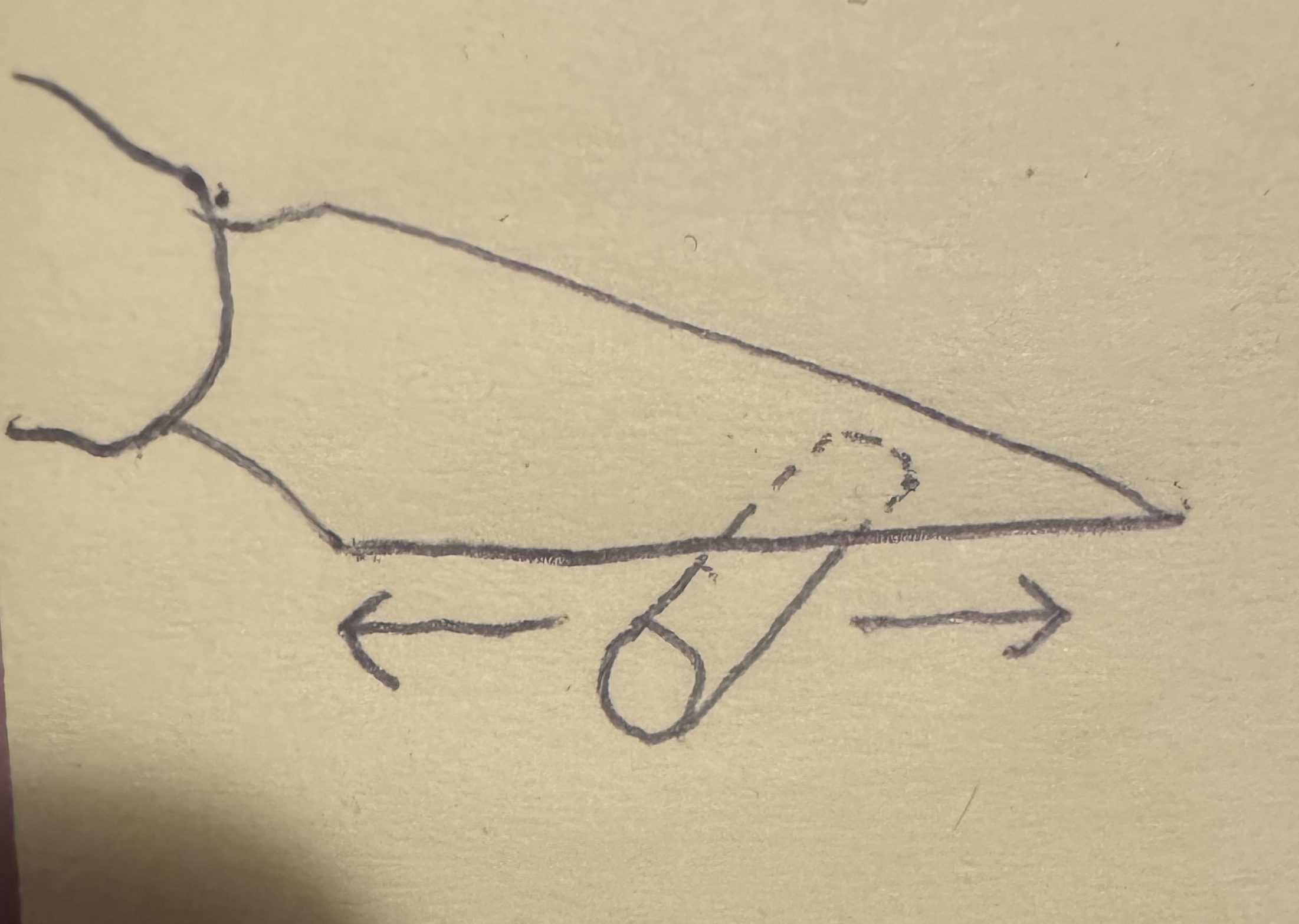

我最近一直在和ChatGPT聊天,聊到我最近一直在为我的机器人制作无刷直流电机控制器,感觉很费力。ChatGPT随机提到集成式半桥功率模块,说我可以利用这种模块来减轻制作电机控制器的工作量。这立刻引起了我的注意,因为我以前从未听说过这种东西,而且它听起来很有意思。我之前一直在自己搭建低侧开关和高侧开关,它们共同构成一个半桥。这需要大量的焊接连接和许多分立元件。而集成式半桥的概念——意味着两个大功率MOSFET以及所有驱动电路都集成在一个芯片上——这将大大减小尺寸并减少元件数量。所以我研究了一下是否有能够满足我的2430无刷直流电机8V 30A需求的集成式半桥模块。结果发现确实有一些这样的产品。起初我考虑的是德州仪器(TI)的CSD95377Q4M半桥驱动器(30A),它可以提供30A的持续电流,非常适合我的需求。但是,我不想被某个特定供应商的芯片所限制,因为这种芯片有一天可能会停产。我更喜欢那种有很多竞争对手生产的、可以在速卖通上买到的通用型产品。这样可以确保我的设计具有前瞻性,不必担心某个制造商停产我使用的零件,导致价格飙升或零件根本买不到。所以,经过一番深入研究,我在速卖通上找到了CSD95481RWJ QFN芯片组,有好几家供应商在销售,而且价格不到1美元一个。也就是说,它相当于两个功率MOSFET加上每个功率MOSFET的所有驱动电路,而价格却不到1美元。这款芯片的持续电流额定值为60A。它的尺寸只有5毫米 x 6毫米,这简直太不可思议了。它比我之前使用的方案小得多,但功率却一样强大。它们通常用于小型降压转换器,并直接用于显卡PCB、服务器、汽车PCB等等。总之,使用三个这样的半桥芯片就可以驱动一个无刷直流电机。将这么多元件集成到如此小的封装中,真是让我大开眼界。所以我订购了 60 个这种芯片——足够驱动 20 个无刷直流电机。如果使用这些芯片比使用我之前用的分立元件更容易,我倾向于将它们用于所有电机控制器。我认为使用它们成本更低——不过我还需要计算一下具体成本。它们甚至内置了温度传感器,我们可以读取温度,这是一个额外的优势。它们的内置电流传感功能不适用于无刷直流电机,所以我仍然需要使用外部的分流电阻电流传感电路,但这没关系。总而言之,这些芯片似乎可以彻底改变现状,减少元件数量,从而减少潜在的故障点,还可以缩小电路板尺寸,使我的电子设备更加小型化,这对我们来说非常有利。我现在还需要研究如何设计相应的 PCB 电路以及需要哪些外部分立元件来支持它。它采用顶部散热方式,这一点也很有意思。我设想使用硅胶导热胶将一个铜垫粘到芯片上,铜垫上已经焊好了编织焊芯线。这些焊芯线会将热量传导到我的水冷管道系统中.

我有点惊讶,似乎没人用这些器件来控制无刷直流电机。它们看起来非常适合这个用途。也许我会引领一股潮流。前提是我不会以惨痛的教训发现为什么没人用它们来做这件事!

注:完整产品名称为:“(5个)100%原装全新 CSD95481RWJ 95481RWJ CSD59950RWJ 59950RWJ QFN 芯片组

注:在我之前的无刷直流电机控制器设计中,我需要使用 6 个数字 I/O 引脚来驱动单个无刷直流电机控制器的 6 个功率 MOSFET 及其控制电路。但对于使用 3 个 CSD95481RWJ H 桥芯片的无刷直流电机控制器设计,我只需要使用微控制器上的 3 个数字 I/O 引脚。这些 CSD95481RWJ H 桥芯片使用一个三态 PWM 引脚——您可以从微控制器向其发送高电平、低电平或浮空信号。数字输出高电平和低电平是常见的数字输出模式,而浮空模式则可以通过在代码中将引脚配置为数字输入引脚来实现。这三种状态输入到芯片后,芯片会输出 V+、V- 或处于关闭/浮空状态。这与我们之前使用分立元件的微控制器设计中使用的标准 H 桥的三种状态完美对应。因此,微控制器上数字 I/O 引脚使用量的减少意味着理论上每个微控制器可以驱动更多电机,这非常棒.

|

发表于 2025-8-22 02:58:19

发表于 2025-8-22 02:58:19

楼主

楼主

发表于 2025-11-3 15:07:55

发表于 2025-11-3 15:07:55